Yamato Living Ramps is more than your average concrete company. We are fuelled by passion for skateboarding. Creative skate spaces and happy users are what we aim for.

Knowing what's what - a hands-on team with skateboarding background doing whatever it takes.

Team-Work... to make the dream work: Experienced building-crews, that turn challenging projects to perfect fit.

»Building skateparks is handing the youths the key to active lives.«

Passion and enthusiasm for skateboarding and crafts. Hands-on to precise form.

Experience, know-how and the fitting spirit for any kind of project.

Yamato consists of about 20 permanent employees, of which most work for industrial purposes. Also included is a permanent planning team, working on designs and execution, project management, company management as well as a master craftsman for masonry and concrete work. And, currently excluding our wages clerk, everyone is actively skating! A good share of our workers have a background in craft (carpentry or concrete work), some are career changers with roots in DIY-skatepark building. By continual further education (i.e. release for non-profit projects, among others) we strive to permanently stay up to speed with structural developments and the latest know-how.

Yamato consists of about 20 permanent employees, of which most work for industrial purposes. Also included is a permanent planning team, working on designs and execution, project management, company management as well as a master craftsman for masonry and concrete work. And, currently excluding our wages clerk, everyone is actively skating! A good share of our workers have a background in craft (carpentry or concrete work), some are career changers with roots in DIY-skatepark building. By continual further education (i.e. release for non-profit projects, among others) we strive to permanently stay up to speed with structural developments and the latest know-how.

Yamato Living Ramps emerged from two of Germany’s most prominent noughties DIY-movements joining forces and professionalising in 2012 – namely: 2er from Hanover and Betonhausen from Berlin. The catalyst had been enthusiasm for skateboarding, the shared desire for better skateparks and discovering new ground paired with the drive to shape and build new terrain. Experiences and merits of those formative years are still part of our DNA and constitute our skatepark-know-how as well as the way we operate.

For our team building a skatepark is far more than the mere work-to-rule. Instead, enthusiasm coupled with knowing the feeling of riding inspiring ramps may even spark innovation – some more minor, some more major. Our diverse team delivers profound and facetted construction- and skateboard-related solutions. Thus, each new park undergoes extensive evaluation.

We’ve pretty much stayed true to initial DIY spirits, following mottos like “Stop bitching, do shit!” and “No skatepark?! Let’s get to work then!” Although, with a master craftsman and a design team we’re a serious business these days, we still burn for what we do. In face of a certainly demanding job, maximising fun times for users ranks on top of our list, not maximising our profits. This is how we went about realising more than 70 projects so far, with hopefully many more to come.

We’re happy to consult in all things constructional and sportive. Be it your journey towards a new park or an obstacle idea for your local DIY. No matter if it’s technical queries realising the Deutsche Einheitsdenkmal with in-situ concrete or the feasibility for a newly found location – we’re here to help. Don’t hesitate to contact us!

Since the options for skatepark design vary immensely and tastes obviously do too, participatory processes for users are top priority. We work with well-tried and tested multi-step formats, that we individually customise towards each project and its user groups.

We ourselves did emerge from two Do-it-Yourself-projects. In organising and hosting the first Builders’ Jam in Hanover in 2012 we also laid the foundation for the building of numerous international skateparks by NGO’s such as MakeLifeSkateLife, Concrete Jungle Foundation or Wonders Around The World. At participatory projects in India and Bolivia Yamato took on a leading role in organisation and site supervision.

The organisation of such participatory events, be it at home at 2er Skateboarding e.V. in Hanover, or the support of local crews close or abroad in realising their dreams, still is heartfelt to us. With qualified social education workers and extensive experience in guidance and motivation of groups, we can help realising a diverse range of ideas, often for project-related special conditions.

As a giant crew of skateboard enthusiasts we’ve been part of an array of projects worldwide, and beyond that we’ve actively skated many, many more. This wealth of experience mirrors in our designs. Most of our skateparks are self-drafted. We offer all necessary steps to realise a skatepark project in-house, from idea to turn-key skatepark. A major benefit here is the direct line between design and execution.

With our in-house steel workshop we can manufacture almost all relevant metalworks ourselves. Therefore, the design team is free to incorporate even intricate features and special components such as adjustable wallrides and movable concrete parts into the planning and make offers at a reasonable price.

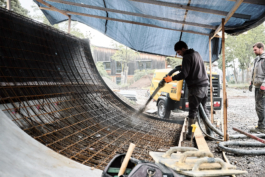

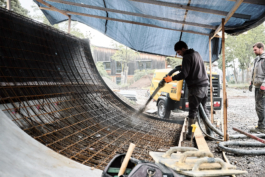

Our core business remains high quality shotcrete manufacturing. Therefore, we use a custom blend of in-situ concrete that is shot onto pre-moulded sub-base and into pre-installed formworks via air-pressure, before being further processed, shaped and trowelled manually. This method enables us to realise far more complex and large construction stages compared to prefab parts. As far as moulding there is virtually no limit – and that with a surface quality that is in no way inferior to machine smoothing.

Our workers are true masters of their trade, adjusting processes, work-cycles and surface conditions each day anew to weather conditions, concrete consistency and desired shape. Artisanry a bit like in the old days, yet with modern technology and material expertise.

Yamato Living Ramps is more than your average concrete company. We are fuelled by passion for skateboarding. Creative skate spaces and happy users are what we aim for.

Knowing what's what - a hands-on team with skateboarding background doing whatever it takes.

Team-Work... to make the dream work: Experienced building-crews, that turn challenging projects to perfect fit.

»Building skateparks is handing the youths the key to active lives.«

Passion and enthusiasm for skateboarding and crafts. Hands-on to precise form.

Experience, know-how and the fitting spirit for any kind of project.

Yamato consists of about 20 permanent employees, of which most work for industrial purposes. Also included is a permanent planning team, working on designs and execution, project management, company management as well as a master craftsman for masonry and concrete work. And, currently excluding our wages clerk, everyone is actively skating! A good share of our workers have a background in craft (carpentry or concrete work), some are career changers with roots in DIY-skatepark building. By continual further education (i.e. release for non-profit projects, among others) we strive to permanently stay up to speed with structural developments and the latest know-how.

Yamato consists of about 20 permanent employees, of which most work for industrial purposes. Also included is a permanent planning team, working on designs and execution, project management, company management as well as a master craftsman for masonry and concrete work. And, currently excluding our wages clerk, everyone is actively skating! A good share of our workers have a background in craft (carpentry or concrete work), some are career changers with roots in DIY-skatepark building. By continual further education (i.e. release for non-profit projects, among others) we strive to permanently stay up to speed with structural developments and the latest know-how.

Yamato Living Ramps emerged from two of Germany’s most prominent noughties DIY-movements joining forces and professionalising in 2012 – namely: 2er from Hanover and Betonhausen from Berlin. The catalyst had been enthusiasm for skateboarding, the shared desire for better skateparks and discovering new ground paired with the drive to shape and build new terrain. Experiences and merits of those formative years are still part of our DNA and constitute our skatepark-know-how as well as the way we operate.

For our team building a skatepark is far more than the mere work-to-rule. Instead, enthusiasm coupled with knowing the feeling of riding inspiring ramps may even spark innovation – some more minor, some more major. Our diverse team delivers profound and facetted construction- and skateboard-related solutions. Thus, each new park undergoes extensive evaluation.

We’ve pretty much stayed true to initial DIY spirits, following mottos like “Stop bitching, do shit!” and “No skatepark?! Let’s get to work then!” Although, with a master craftsman and a design team we’re a serious business these days, we still burn for what we do. In face of a certainly demanding job, maximising fun times for users ranks on top of our list, not maximising our profits. This is how we went about realising more than 70 projects so far, with hopefully many more to come.

We’re happy to consult in all things constructional and sportive. Be it your journey towards a new park or an obstacle idea for your local DIY. No matter if it’s technical queries realising the Deutsche Einheitsdenkmal with in-situ concrete or the feasibility for a newly found location – we’re here to help. Don’t hesitate to contact us!

Since the options for skatepark design vary immensely and tastes obviously do too, participatory processes for users are top priority. We work with well-tried and tested multi-step formats, that we individually customise towards each project and its user groups.

We ourselves did emerge from two Do-it-Yourself-projects. In organising and hosting the first Builders’ Jam in Hanover in 2012 we also laid the foundation for the building of numerous international skateparks by NGO’s such as MakeLifeSkateLife, Concrete Jungle Foundation or Wonders Around The World. At participatory projects in India and Bolivia Yamato took on a leading role in organisation and site supervision.

The organisation of such participatory events, be it at home at 2er Skateboarding e.V. in Hanover, or the support of local crews close or abroad in realising their dreams, still is heartfelt to us. With qualified social education workers and extensive experience in guidance and motivation of groups, we can help realising a diverse range of ideas, often for project-related special conditions.

As a giant crew of skateboard enthusiasts we’ve been part of an array of projects worldwide, and beyond that we’ve actively skated many, many more. This wealth of experience mirrors in our designs. Most of our skateparks are self-drafted. We offer all necessary steps to realise a skatepark project in-house, from idea to turn-key skatepark. A major benefit here is the direct line between design and execution.

With our in-house steel workshop we can manufacture almost all relevant metalworks ourselves. Therefore, the design team is free to incorporate even intricate features and special components such as adjustable wallrides and movable concrete parts into the planning and make offers at a reasonable price.

Our core business remains high quality shotcrete manufacturing. Therefore, we use a custom blend of in-situ concrete that is shot onto pre-moulded sub-base and into pre-installed formworks via air-pressure, before being further processed, shaped and trowelled manually. This method enables us to realise far more complex and large construction stages compared to prefab parts. As far as moulding there is virtually no limit – and that with a surface quality that is in no way inferior to machine smoothing.

Our workers are true masters of their trade, adjusting processes, work-cycles and surface conditions each day anew to weather conditions, concrete consistency and desired shape. Artisanry a bit like in the old days, yet with modern technology and material expertise.

Yamato Living Ramps GmbH

+49 511 7902 5090

kontakt@yamatoramps.de

Kötnerholzweg 13

30451 Hannover (GER)

©Yamato Living Ramps, All Rights Reserved. Design, Development: Christian Vukomanovic

Yamato Living Ramps GmbH

+49 511 7902 5090

kontakt@yamatoramps.de

Kötnerholzweg 13

30451 Hannover (GER)

©Yamato Living Ramps, All Rights Reserved.

Design, Development: Christian Vukomanovic